Why Australian Laser Cleaning?

Unique Benefits of Laser Cleaning

Non Abrasive & Zero Contact

Environmentally Friendly

No Chemicals or Waste

Quick & Efficient Mobile Service

How Does Laser Cleaning Work?

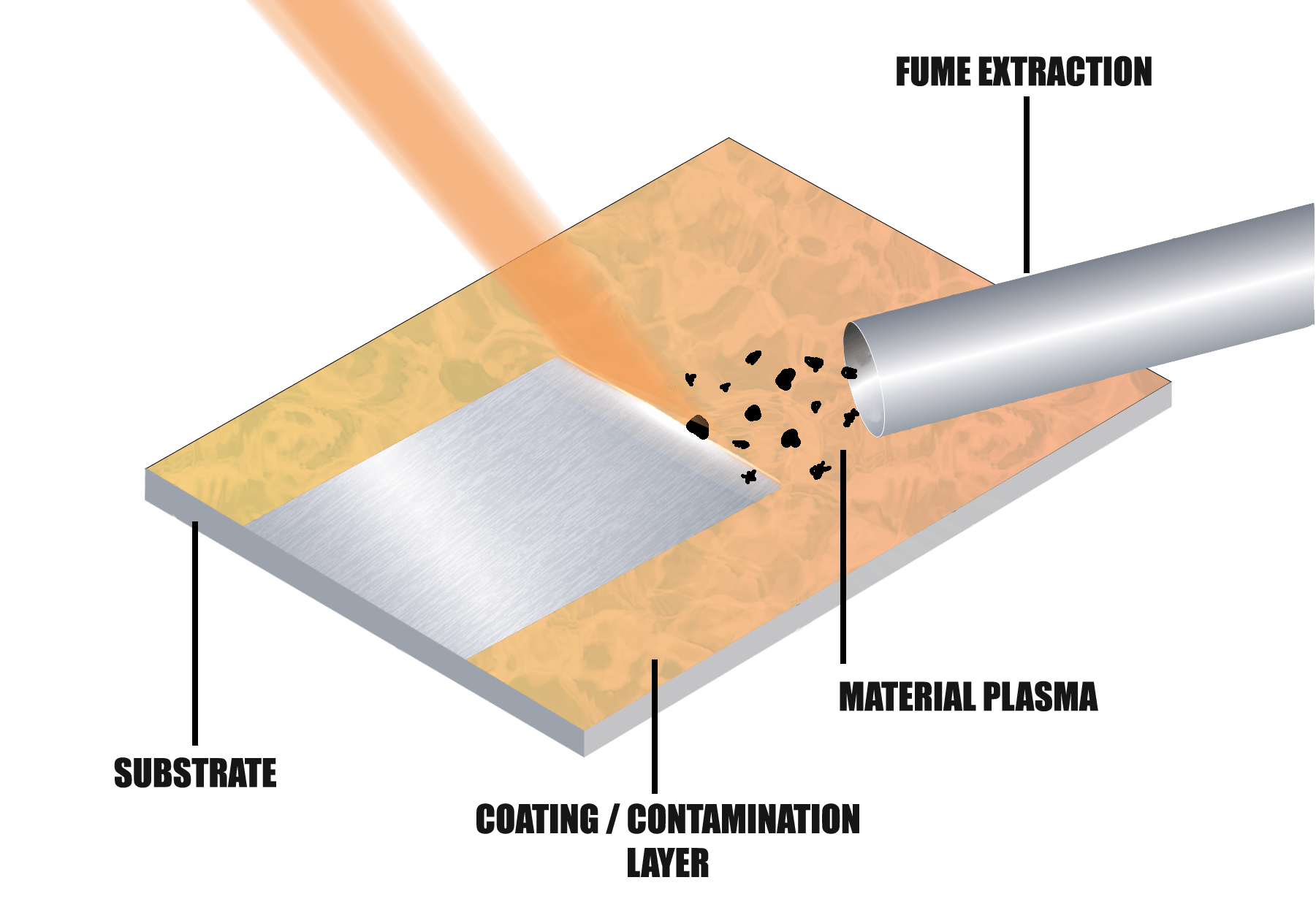

Our Laser Cleaning Machines use ultra-short, high-energy pulses of light to detach and vaporise unwanted contaminants and coatings with no damage to the substrate. Each coating or contaminant requires specific settings to ensure that the surface is cleaned sufficiently and the substrate unharmed.

While all cleaning methods have hazards, laser cleaning is a safe and effective method of industrial cleaning when applied correctly. We use certified laser filtered safety glasses, multi-level fume extraction and filtration equipment and laser safety screens to ensure we keep our employees, customers and the public safe when operating our equipment.

Laser Graffiti Removal Before and After

Laser Cleaning Services

- Rust removal

- Graffiti removal

- NDT preparation

- Soot and smoke Cleaning

- Anodising & Iridite removal

- Weld prep and post cleaning

- Coatings and paint removal

- Heritage and stone cleaning

- Lead Paint Removal

- Oxide Removal

- Magnetite removal

- Oils and Fats cleaning

- Heat Exchanger plate cleaning

- Residue Removal